Description

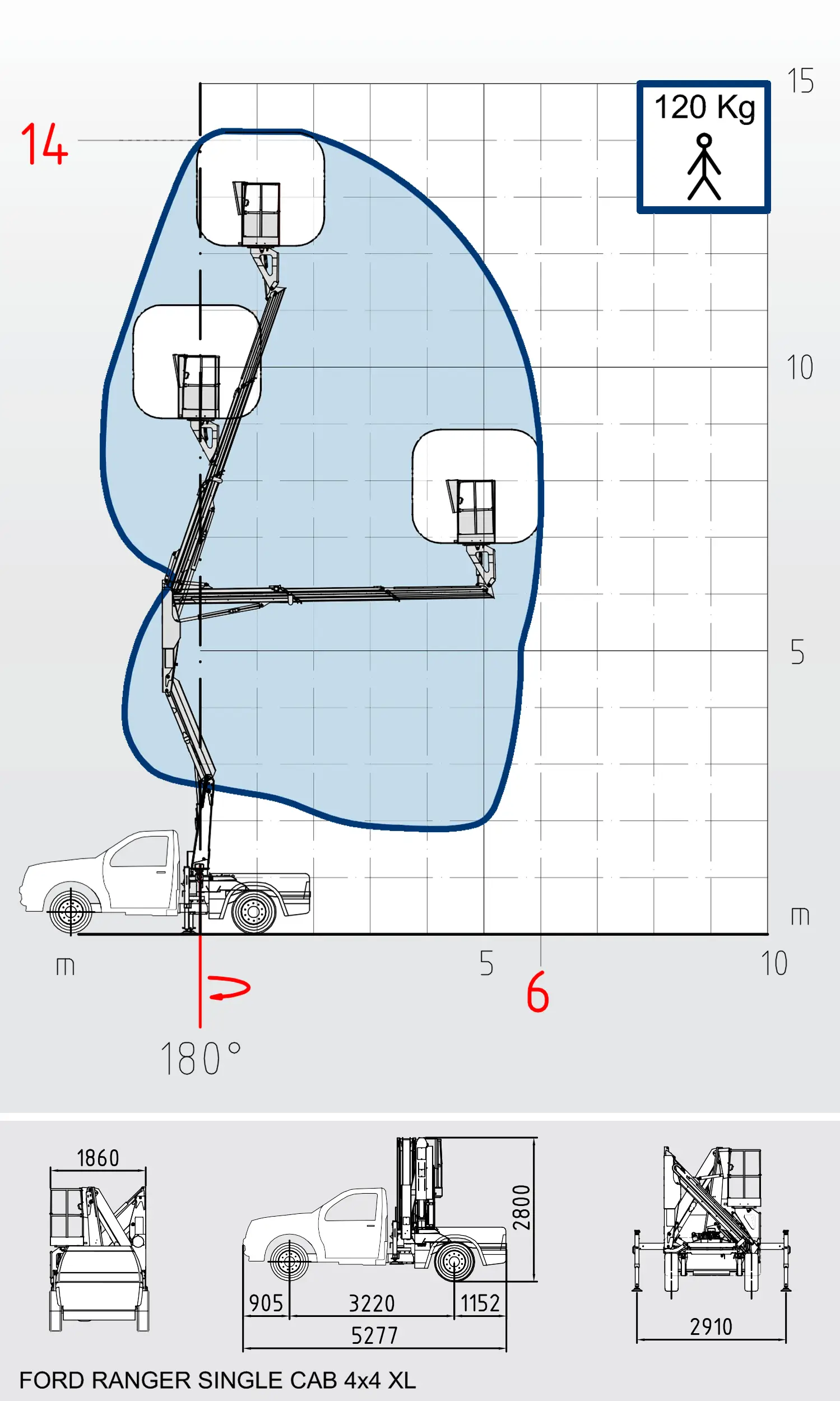

The Pick Up Solutions X4 12 aerial platform installed on Iveco, Nissan or Renault pick-ups is the ideal solution for working safely at a height of up to 14 metres with a horizontal outreach of 6.5 metres.

- CAPACITY IN THE BASKET 120 Kg – 1 person

- HYDRAULIC STABILIZERS n.2 in shape

- 180° ROTATION

- 100% low pressure hydraulic controls

- MINIMUM INSTALLATION GVW 2.9 tons

- Aerial platform made of high-resistance steel to ensure maximum rigidity of the arm and maximum safety during work .

- Base part that anchors the platform to the truck and serves to rest the platform on the ground by means of the stabilizers.

- Stability is ensured by 2 IN-SHAPE stabilizers operated by lever controls. The pair is formed by two double-acting hydraulic jacks connected to the main circuit.

- Turret with dual functionality: arm support and rotation organ. It emerges from the base and rotates, thanks to a system moved by a hydraulic motor and a fifth wheel. Inside it is placed a piston that raises the pantograph.

- Pantograph to open the platform, raising the telescopic arm. The maximum height of the pantograph corresponds to the maximum height of climbing. The pantograph is composed of 2 arms, connected to each other by a head, which move simultaneously.

- Telescopic arm consisting of 2 elements, 1 of which is extendable . The positioning of cables and pipes inside the special pipe-holder chain guarantees protection against impacts, accidental falling tools, etc. The arm allows the platform’s work area to be developed vertically and horizontally.

- The basket is intended to protect and support operators working at height. The platform’s maneuvering controls are located on the nacelle.

- Free container for loading materials and work tools.

- Hydraulic oil tank in easy-to-access position for checking and refilling the level.

- 100% hydraulic controls for precise and millimetric movements. Thanks to the hydraulic system, a very long life of the system is guaranteed with very low maintenance costs.

- The frame and arm are made of high-strength steel tubes, which ensure high stability for the entire platform.