Description

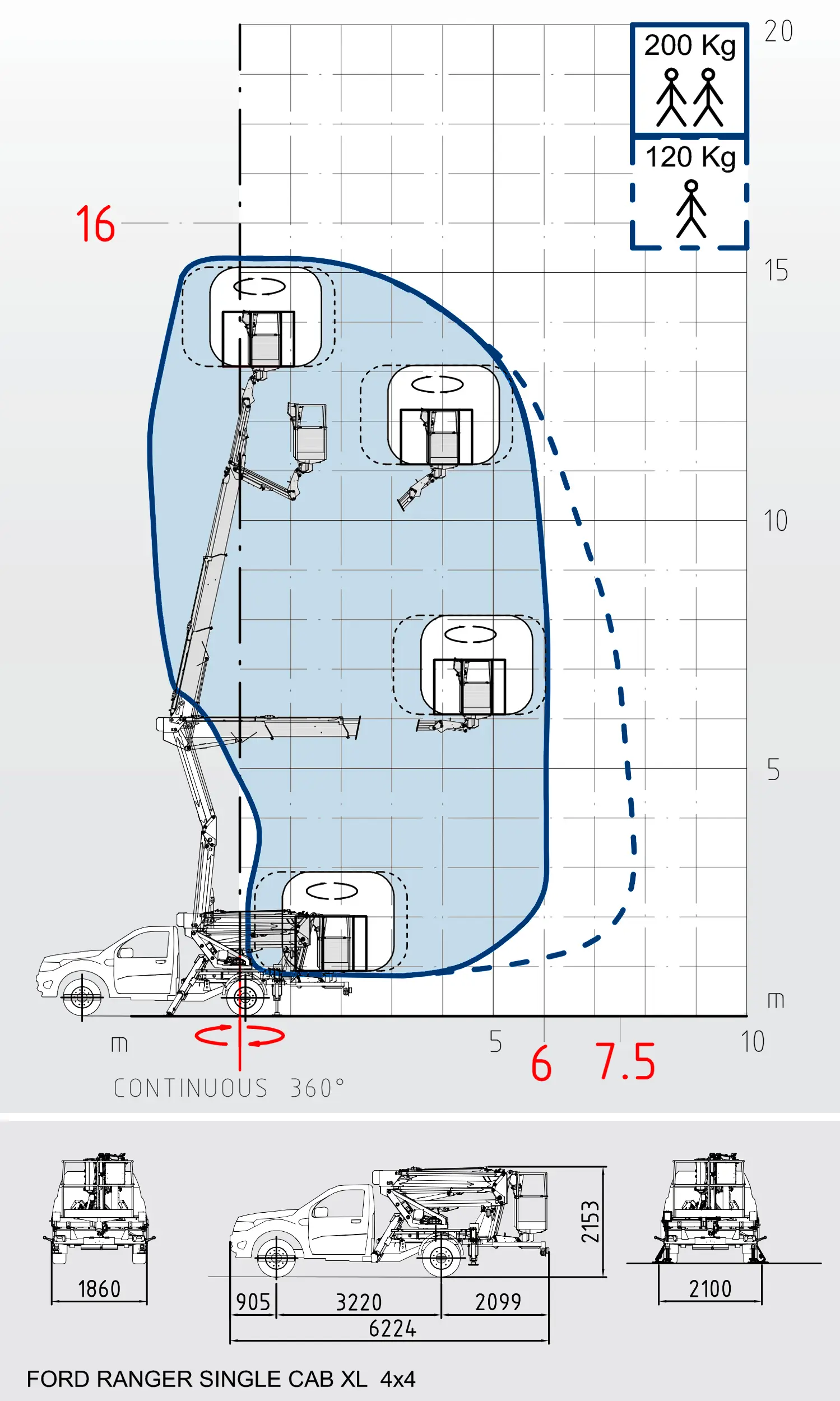

The New Eurosky 16|2|6 (7.5) HQ JIB aerial platform is the ideal solution for working safely at a height of up to 16 metres with a horizontal outreach of 6 or 7.5 metres.

- HYDRAULIC STABILIZERS n.4

- Continuous 360° ROTATION

- 100% low pressure hydraulic controls

- MINIMUM INSTALLATION GVW 2.2 ton

- Aerial platform made of high-strength steel to ensure maximum rigidity of the arm and maximum safety during work.

- Base part that anchors the platform to the truck and serves to rest the platform on the ground by means of the stabilizers.

- Hydraulic oil tank integrated into the platform frame in an easily accessible position for checking and refilling the level.

- Stability is ensured by N.4 stabilizers. Each pair is formed by two double-acting hydraulic jacks connected to the main circuit.

- Turret with double functionality: arm support and rotation device. A hydraulic motor coupled to an irreversible VSF reducer allows continuous 360° rotation on a fifth wheel. A rotating distributor makes hydraulic connections between the fixed and rotating parts possible, avoiding twisting of the pipes.

- Double pantograph to raise the platform without changing the position of the nacelle with respect to the center of the fifth wheel. The maximum height of the pantograph corresponds to the maximum height of climbing. The pantograph is composed of 2 arms, connected to each other by a head, which move simultaneously.

- Telescopic arm consisting of 2 elements, 1 of which is extendable. The positioning of cables and pipes inside the arm guarantees protection against impacts, accidental falling tools, etc. The arm allows the platform’s work area to be developed vertically and horizontally.

- Articulated final arm (JIB) is used to climb over and overcome obstacles in the work area. It is located at the end of the telescopic arm, offering the possibility, even at height, to reach otherwise inaccessible working positions.

- The basket is intended to protect and support operators working at height. The platform’s maneuvering controls are located on the nacelle.

- 100% hydraulic controls with low pressure proportional system in the nacelle (only 25 BAR) for precise and millimetric movements. Thanks to the low pressure hydraulic system, a very long life of the system is guaranteed with very low maintenance costs.

- The frame and arm are made of high-strength steel tubes, which ensure high stability for the entire platform.

- Lateral outreach up to 6m with a 200kg capacity in the basket (2 pers.) and lateral outreach up to 7.5m with 120kg (1 pers.)