Description

Leopard 25 Tracked Aerial Platform

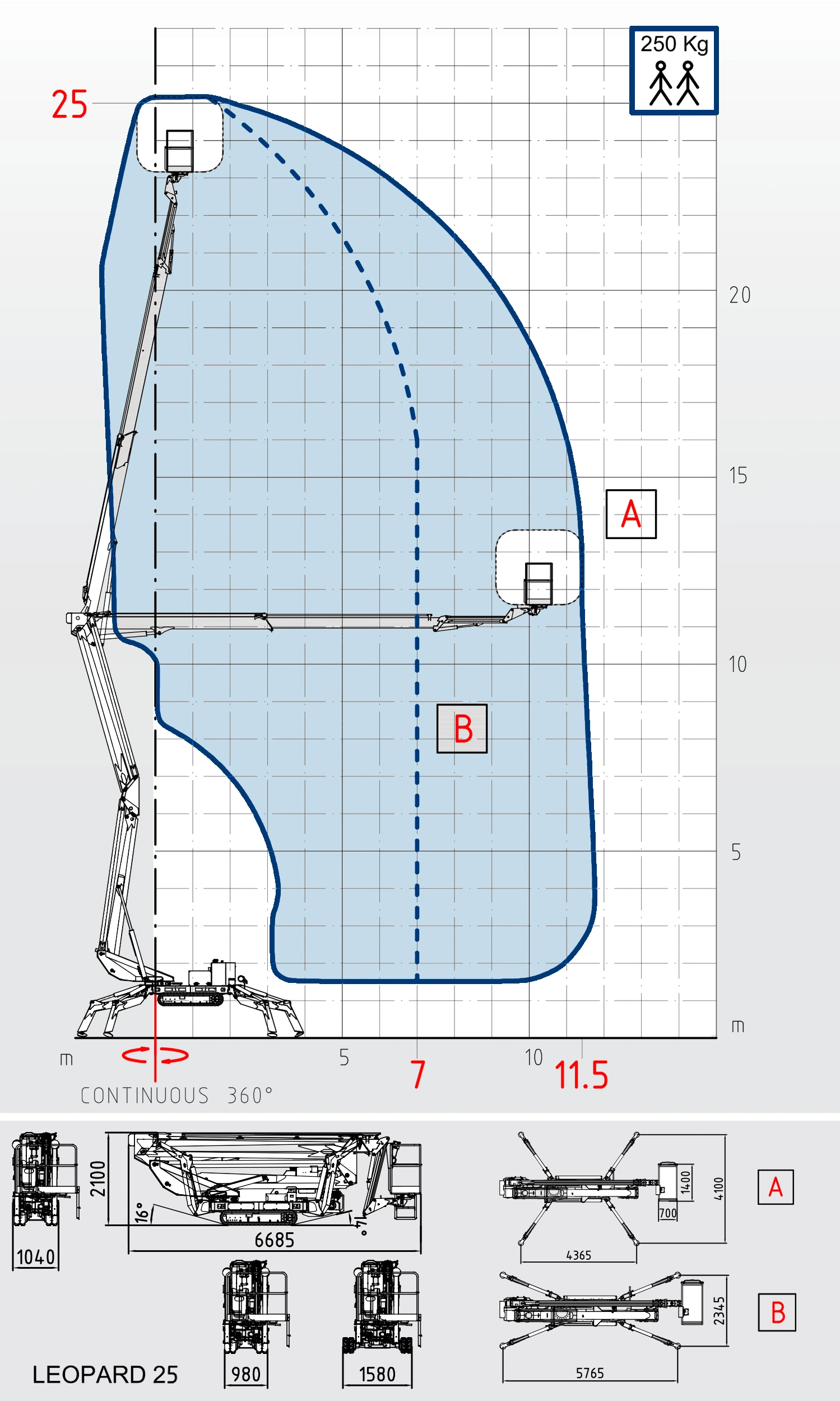

The Leopard 25 is designed for safe operation at heights up to 25 meters with a horizontal outreach of 11.5 meters, providing great stability and flexibility.

Key Features:

- Hydraulic Stabilizers: 4 stabilizers for enhanced stability.

- 360° Rotation: Full rotation for flexible positioning.

- 100% Electro-Hydraulic Controls: Smooth and precise control with proportional adjustments.

- Power Options: petrol engine/lithium batteries for reliable performance.

- Minimum Installation GVW: 3.5 tons.

Platform Details:

- Durable Construction: Built from high-strength steel to ensure arm rigidity and safety.

- Hydraulic System: 100-liter oil tank integrated into the frame for easy maintenance.

- Stability: 4 stabilizers with double-acting hydraulic jacks ensure a stable work environment.

- Rotation: Turret with 360° rotation for flexible and precise positioning.

- Telescopic Arm: 3-section arm (1 fixed + 2 extendable) for vertical and horizontal reach, with protective cable and pipe management.

- Nacelle: Protects and supports operators at height, with platform controls located in the nacelle.

- Proportional Electro-Hydraulic Controls: Provides smooth, gradual, and precise movements.

- Tilt Tolerance: Can tilt up to 30% for added flexibility.

Additional Specifications:

- Speed: Two speeds – 0.8 km/h and 1.3 km/h.

- Platform Dimensions: Length 6685 mm, Width 1040 mm, Height 2100 mm.

- Basket Dimensions: Length 1400 mm.

- Total Weight: 4200 kg.

The Leopard 25 platform offers a reliable and safe solution for high-reaching tasks, ensuring operator safety, stability, and precision.